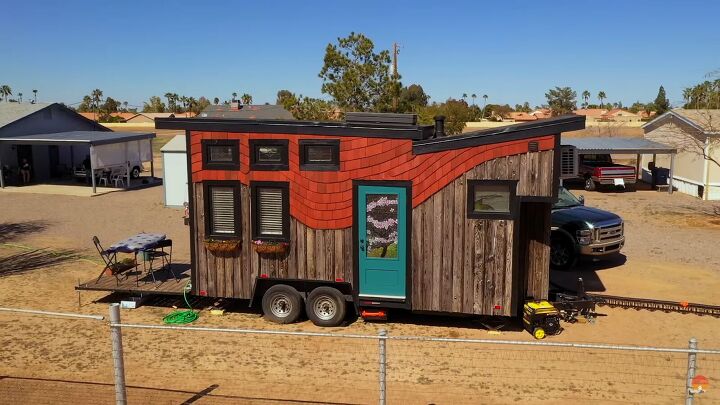

Building a Tiny House With Recycled Materials

We love telling you about tiny houses all around the country and the wonderful stories of their owners.

Today, we are interviewing Jen and Dave about their experience of building a tiny house on wheels with recycled materials. If you want to learn more about how to build a tiny house, stay tuned!

Who came up with the idea of building a tiny house?

Dave: It never occurred to me to do it until a random conversation we had on vacation to the Outer Banks, where Jen asked me if I had ever heard of tiny houses. I said yes, and she said we should build one, so I said okay!

And then we just spent the rest of the vacation talking about it. I remember our youngest daughter said, “You guys better not flake out”, because we are flaky people.

What helped you most to plan your recycled tiny house?

Jen: We did a lot of research, we watched thousands of hours of YouTube. Tiny houses are not mainstream, but they have definitely been around for a while now.

Those pioneers have worked out a lot of kinks, and we were able to learn from their pitfalls and not fall into the same holes. So far it is working out.

How much did it cost to build the tiny house, and how tiny is it?

The house is 157 square feet, with the dimensions of 20’*8.5’*13.2’. The total cost was around $32K.

Where did you source your materials?

Dave: We did not buy a lot of retail. The framing material, plywood and all that was retail, but everything else came from lumber auctions, marketplaces, Craigslist and just hunting for the right materials.

Jen: There is a saying I like that goes “You can save money or you can save time, but you cannot do both”.

Dave: I drove four and a half hours one way to pick up all the shingles for the walls from a general contractor that had been collecting them for years, and it is the same story for most of the materials.

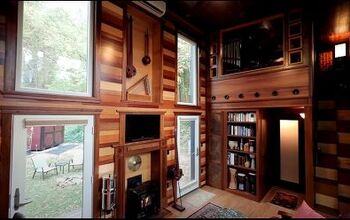

We built our own window frames using reclaimed lumber, and for the rest of the wood we bought raw lumber at the lumber mill. I spent hours upon hours working on a jointer. Short of cutting trees, I did everything.

How long did the build take?

Jen & Dave: From conception to finish, it was four years. It took us a good year to get started and plan the design, since we did not really know what we were doing.

We drew the complete blueprints and started the build in our friends’ driveway, since we were living in the city and had street parking, so they were nice enough to offer us the space they had.

How did you come up with the elevator bed?

Jen: We knew that a bed that goes up and down was the solution for us, but since it is not a traditional loft we then were faced with this tiny 8*20 footprint where we had to squish both the bathroom and the kitchen at the front of the trailer.

Dave: We actually got this idea from Ana White’s YouTube channel. They were building a tiny house around that time for a customer who wanted an elevator bed, so we stole that idea from them.

Jen: Most of this build was inspired by other people on YouTube. We got the ideas from there, and then we were only able to execute it from watching everybody else do it before us.

Dave: We built the bed from scratch in the workshop, and then brought it here and reassembled it because the frame was too big to fit through the door.

I built it, did all the drive fits, took it apart, painted and clear coated everything individually, then brought it here and reassembled it. This means, like with most other things in here, that if we ever have to do maintenance or repairs, I know how to take it apart.

What was working with steel framing like?

Dave: That was a big challenge. As opposed to a stick build, a steel frame does not allow you to cut a new hole and put in a new sticker to replace it. With steel 2*4s, you are stuck with the original frame, and it does cost a lot of money, so I would not do that again.

Why did you choose a butterfly roof?

Jen: It looks like the parts of our roof collapse on each other, and that is not an accident. We did it for a water collection. The front part is angled, so the water always comes down in one corner.

It is a poor design, since now all the water runs off in front of one window, but we did it so that later on we can add a removable water catchment if we wanted to, and we would not have to redesign.

What were the most challenging and the most rewarding parts of the build?

Dave: I definitely did not enjoy all of it. Most days I hated staring at this project, since I was working on it all of the time.

Now that it is done, I can finally appreciate the unique look and how beautifully it all came together, and even find beauty in the imperfections. A lot of the stuff I brought here looked like trash back then, but after a whole lot of work it turned out great.

Any advice for future DIY builders?

Dave: Our mistake was not hiring a professional to do the blueprint before we started building. If you do not have any construction or contracting background, spend the money up front and let a professional do your blueprint.

They are trained to do all your system placements, they will know where the studs and the walls need to be in order to cut out for vents or water lines, and so much more. Saving yourself all of that headache is worth every penny.

Building a tiny house with recycled materials

Would you ever move into a tiny home? Do you believe you could build one yourself? And if you already are or have, what is the biggest challenge and what is your favorite part? Share in the comments!

Comments

Join the conversation